ABOUT VERSA AGRO INDUSTRIES

Our elders started their journey of VERSA AGRO INDUSTRIES with the manufacturing of agriculture implements in 1972. They were pioneer in manufacturing agriculture implements like Plough Harrows, Wheat Threshers, MB Plough, and Cultivators etc. We at VERSA have always tried best to deliver best to our esteemed customers. In 1999 we started Manufacturing Harvesting Blades. We started the production of harvester blades at a time when there was a huge demand for it and very less production. But today we have beaten demand by increasing the production and quality. Today we are one of the leading manufacturers of HARVESTER BLADES in India. Today VERSA is leader in Indian market and one of the main players in the field of cutting systems in India. Along with this we also started manufacturing BENCH PLANE BLADES. We have always tried to make blades life long and tough and for that we developed new methods by which this can be achieved. The quality, the professionalism in being able to recommend the right product and the performance are the best guarantee of customer satisfaction. That is why our motto is “COMPETITION IS AN OPPORTUNITY FOR GROWTH. WE FIGHT IT WITH GOOD QUALITY”

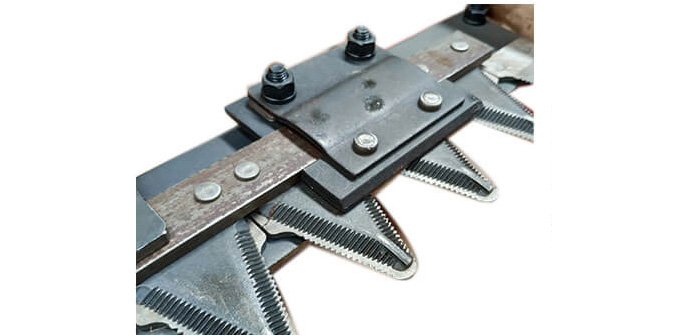

KNIFE/SICKLE SECTIONS OF HARVESTER MACHINES

KNIFE SECTIONS are used in Harvesting Machines like Combine Harvesters (New Holland, John Deere, Claas, IH Case, Laverda, BSC etc.), Mowers, Straw Reapers and Threshing Machines. Versa is chosen by agricultural machinery manufacturers as first equipment, by the best aftermarket parts distributors and by farmers demanding more care of their tools. The standard production counts more than 100 different blades for agriculture, gardening, and also many blades are made in client requirement.

BENCH Plane Blades for Bench Planes

Bench Planes are used by carpenters for shearing wood. As were already making precision harvesting blades, the hunger to make more quality products pushed us to start the production of Bench Plane Blades too. These blades too demand very high quality standards as they are used in hand tools by carpenters. These blades are Hardened, tempered and high-carbon chrome steel assures excellent edge retention, Can be honed to a razor-sharp edge and Ground to a flat surface for easy sharpening.

EN42J Steel, Induction hardened to Rockwell 60-62 and double tempered. Our heat treating technique ensures that the blade will take and hold a very fine edge for a long time. After heat treating, the blade is fully surface ground on the top, back, and cutting edge, giving a smooth, flat surface that will take a mirror finish very quickly. Our blades are of required thickness to provide solid, chatter-free cutting.

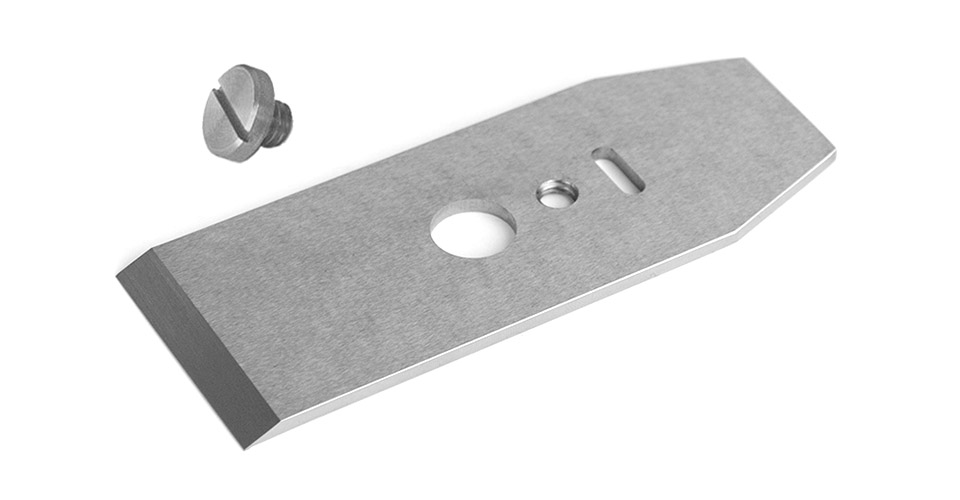

Chipbreaker

Chipbreakers are designed specifically to company Bench Plane Blades. It is possible that they may fit some original Stanley or Record planes, but critical dimensions of these and other maker's tools varied over the years.

Our chipbreakers are made of High Carbon Tool Steel and are 3 mm thick with a .40 mm lip ground at a 2 degree angle to provide excellent contact between the leading edge of the chipbreaker and the blade. Our each chipbreaker is supplied with a screw.